| NEWS |

| Product Knowledge |

Pharmaceutical production environment cannot be ignored

Drug of humid air is very sensitive, especially drug powder and tablets absorbs wet get damp, once absorb excess moisture in the air easy to lose value.In addition, if long time under high humidity environment, will cause the corrosion of the equipment surface, increase the maintenance cost, reduce the production efficiency.Therefore, control the temperature and humidity of the environment is a key link in the process of production to be reckoned with, and directly affect the product quality and production efficiency.

Conventional drugs production standards

Tablet and coating, booster injection, producing the packaging, soft capsule dry -

Temperature: 20 ℃

Require humidity: RH40 %

Fluidized bed, effervescent tablets

Temperature: 20 ℃

Require humidity: RH25 %

Laboratory, drug storage -

Required temperature: 22 ℃

Require humidity: < RH40 %

The blood test -

Required temperature: 22 ~ 25 ℃

Require humidity: RH12 ~ 20%

- soft capsule production workshop

The required temperature 25 ℃ + / - 3

The required humidity: RH25 % + / - 3

A classic case

customers

The customer for a domestic well-known pharmaceutical companies, lianyungang has a 70 m3 workshop need dehumidifier, workshop staff 5 people, no other indoor heat source of moisture, request the target temperature 25 ℃ or less and relative humidity of 30% or less, customer no cold source and heat source.

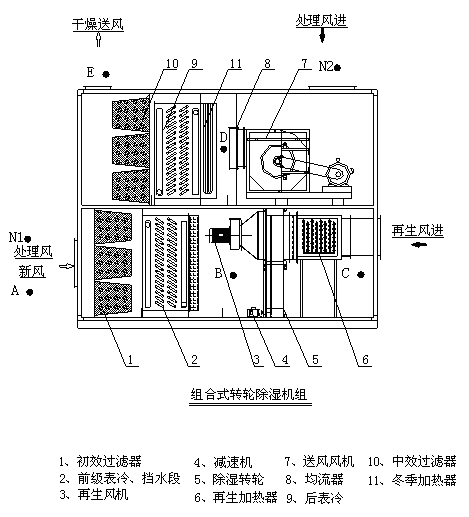

Can Lin Yier solution

Its process is added a little fresh air after mixed with drying room return air precooling the dehumidifying period of depth wheel dehumidification process, then through

Cooling treatment to low temperature and humidity drying air, into the drying room.

In this way new rheumatism between load and dry wet load by the assembled dehumidified before cooling unit and wheel dehumidifier, dehumidifier period of increase of heat load and dry inside the heat load borne by after cooling.

According to customer's requirement, can Lin Yier for customers to choose 1600 CMH composite desiccant wheel unit, considering staff, indoor design CMH 200 fresh air, 1400 CMH return air, the whole units equipped with filtering effect in the early period, before the table cold, mixing section, wheel dehumidifier, table after cold and effect in the filter.

Technological process and design parameters:

State point air flow temperature relative humidity, water content of enthalpy

M3 / h ℃ % g/kg dry air KJ/kg dry air

A new wind 200 35 200 30.4 108.93

B table cold period of 200 to 14 200 9.57 38.31

Return period of 22 to 28, 4.63 1000 34

Mixed 1000 20.7 35.6 5.45 20.7

37 C wheel section 1000 4.73 1.85 42.12

D 1600 and 5.58 3.5 39.08

E 1600 18 to 35 3.5 30.87

A return 800 25 to 30 6.1 40 N1

N2 secondary return air 600 25 to 30 6.1 40

Shanghai wet and electrical equipment co., LTD., according to customer needs, combined with the customer's existing energy, to make economic and energy saving technical solution, temperature and humidity control precision, reliable product performance, as the industry's leading dehumidification partners, wet the electric will serve you wholeheartedly.